化学气相沉积法制备的高纯度(97%)可控直径的半导体碳纳米管

(刻蚀剂在化学气相沉积法制备半导体碳纳米管富集的生长过程中的双重作用)

Confirming the Dual Role of Etchants during the Enrichment of

Semiconducting Single Wall Carbon Nanotubes by Chemical Vapor

Deposition

Imad Ibrahim,†,‡ Jana Kalbacova,§,∥ Vivienne Engemaier,† Jinbo Pang,† Raul D. Rodriguez,§,∥

Daniel Grimm,† Thomas Gemming,† Dietrich R. T. Zahn,∥,§ Oliver G. Schmidt,†,‡ Jürgen Eckert,†,‡,⊥

and Mark H. Rümmeli*,†

DOI: 10.1021/acs.chemmater.5b02037

Chem. Mater. 2015, 27, 5964−5973

IF: 8

中文摘要:

特定电子类型的半导体碳纳米管在超越硅材料方面,拥有巨大的潜力。尽管工艺和机理方面存在巨大挑战,人们始终追寻着优化合成单笔碳纳米管的方法。本文我们就三个方面对半导体富集的单笔碳纳米管的生长进行研究。这三个方面是催化剂的类型,衬底以及碳源气体的混合。在半导性的碳管产率方面,二元催化剂以及衬底几乎没有影响。然而,

当在乙醇(碳源进料)中添加适量甲醇后,我们发现这种半导体碳管的富集现象尤为显著。用这个方法,我们得到了高达97%产率的半导体单壁碳管。这得益于刻蚀剂的两个作用过程。一方面,金属单壁碳管可以被优先刻蚀。另一方面,刻蚀剂优先刻蚀较小直径的单壁碳管(因为小直径碳管不稳定,更易于反应)。刻蚀剂扮演了双重角色,优先刻蚀金属碳管和小直径碳管(包括金属性的和半导体性的),这减小了单壁碳管直径的的分布区间(达到更高的均一性)。

英文摘要

The search for ways to synthesize single wall carbon nanotubes (SWCNT) of a given electronic type in a controlled manner persists despite great challenges because the potential rewards are huge, in particular as a material beyond silicon. In this work we take a systematic look at three primary aspects of semiconducting enriched SWCNT grown by chemical vapor deposition. The role of catalyst choice, substrate, and feedstock mixture are investigated. In terms of semiconducting yield enhancement, little influence is found from either the binary catalyst or substrate choice. However, a very clear enrichment is found as one adds nominal amounts of methanol to an ethanol feedstock. Yields of up to 97% semiconducting SWCNT are obtained. These changes are attributed to two known etchant processes. In the first, metal SWCNT are preferentially etched. In the second, we reveal etchants also preferentially etch small diameter tubes because they are more reactive. The etchants are confirmed to have a dual role, to preferentially etch metallic tubes and narrow diameter tubes (both metallic and semiconducting) which results in a narrowing of the SWCNT diameter distribution.

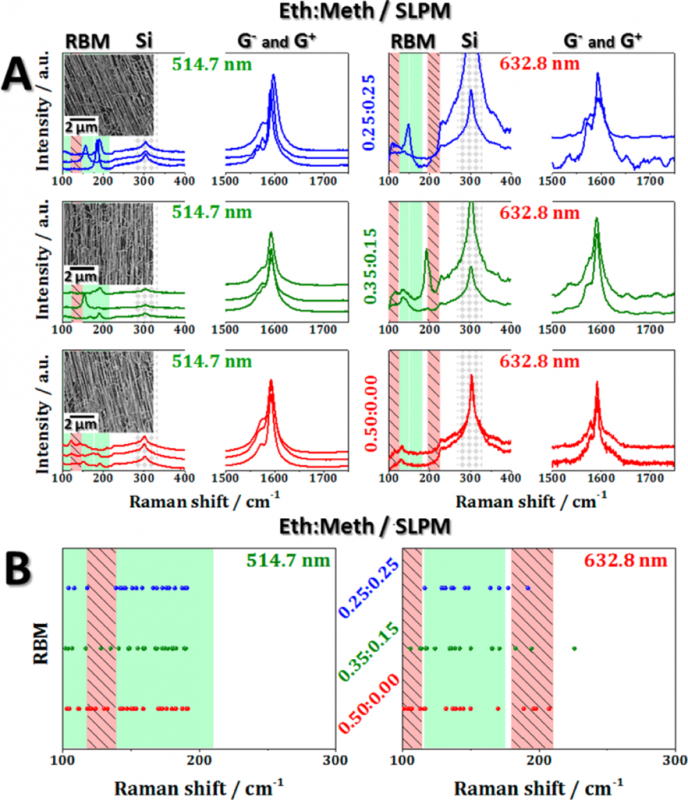

Figure 2. Effect of carbon precursor: A. representative Raman spectra and SEM images (inset) for the SWCNT grown over ST-cut quartz using a

binary catalyst system (Fe:Co = 2:1 molar ratio) and different combinations of C precursors and B.

碳源进料(乙醇和甲醇的相对流速)的影响:

(石英上的单壁碳管)拉曼谱以及扫描电镜图。(二元铁钴催化剂)

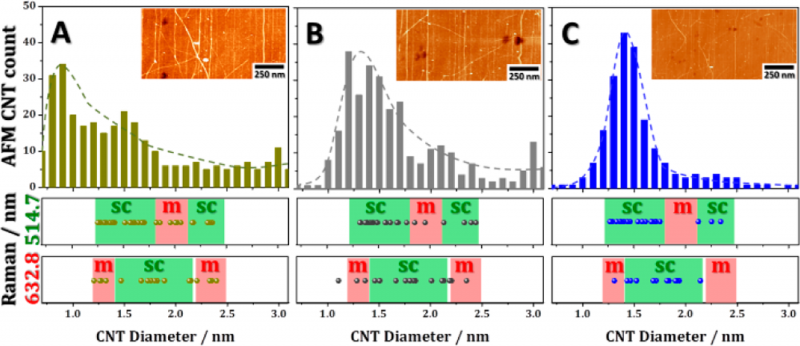

Figure 4. Diameter distribution of grown SWCNT with respect to feedstock mix: Diameter histogram of SWCNT grown on ST-cut quartz measured with AFM (upper row) and Raman spectroscopy (lower rows). The reduction in diameter distribution width from the formation of fewer narrow diameter tubes is obvious and is attributed to preferential etching by radicals of narrow diameter tubes (upper row) and concomitant RBM responses from Raman spectroscopy (lower two rows) when using Eth:Meth flow rates equal to A. 0.50:0.00, B. 0.35:0.15, and C. 0.25:0.25 (SLPM) (left to right). Inset: Representative AFM images for the grown CNTs. Dotted lines in the upper row are a guide for the eye.

碳源混合比决定的碳管直径分布。上图为AFM测试直径的统计直方图(内嵌入图为AFM表面形貌

)。下图为通过拉曼RBM峰位计算的碳管直径分布。ABC 为乙醇甲醇的相对流速比。从左到右依次是0.5:0,0.35:0.15,0.25:0.25 (standard liter per minute).

Figure 6. In situ voltage contrast SEM identification of SWCNT: The

change in contrast of tubes confirms enrichment of semiconducting

SWCNT due to the introduction of methanol. Inset: Representative

SEM images of SWCNT grown under different conditions in between

metallic electrodes without and with applying an external bias. Light

and dark green arrows indicate nanotubes due to sudden cut and no

change in CNT contrast, respectively. Red arrows indicate m-CNTs by

exhibiting a gradual change in contrast, i.e. uniform potential

distribution along the tube axis. Scale bar = 1 μm.

在线电压衬度的扫描电镜,对半导性碳纳米管的确认。所观察的碳管,两端镀有电极,左边SEM加电压,右边SEM不加电压。不加电压时,碳管显示了均一的衬度。而施加电压后,金属管和半导管显示了衬度迥异的图像。

红色箭头代表金属管,在施加电压时,其显示了沿着轴向的衬度变化,代表着每个点处的电势的不同。淡绿色和深绿色箭头代表半岛管。其中深绿色显示了没有衬度变化,而淡绿色显示了衬度在碳管左端(接触电极处)的突然变化,显示了金属-半导体接触的二极管特性。

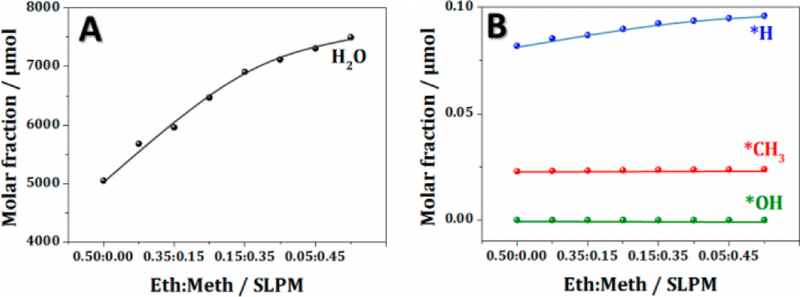

Figure 8. Molar fractions for etchants for various ethanol:methanol mixture ratios from thermodynamic calculations (temperature = 900 °C). Lines

are a guide to the eye.

热裂解产生的刻蚀剂(H2O和H*)随着乙醇—甲醇流速比率的变化。(900C下的热力学平衡态的计算)

证实了(在实验过程的)比率为0.25:0.25(相对最强)下,其刻蚀作用最强,碳管直径分布区间最窄。

|

![]()